Quick Freezing Equipment

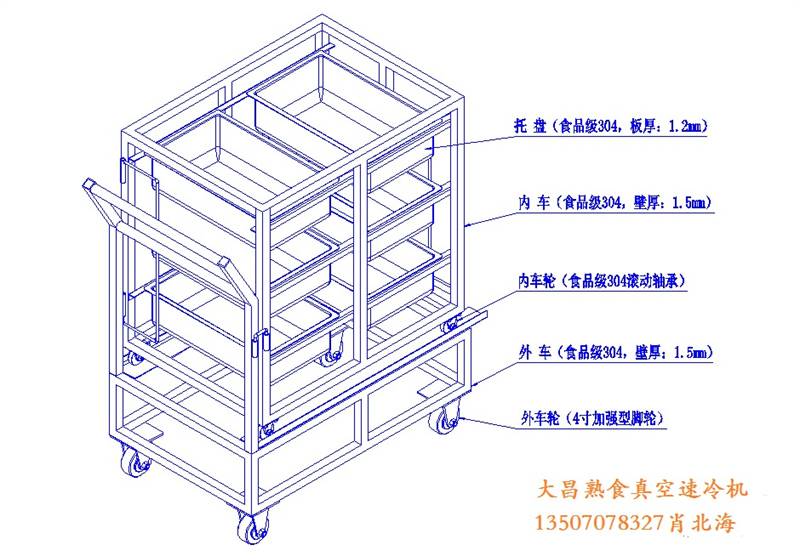

A rapid vacuum cooler is a device used to quickly cool hot objects. It achieves rapid cooling by placing a high-temperature object in a vacuum environment and cooling it with a coolant. Such equipment is commonly used in laboratory research, industrial production and medical fields. The working principle of the rapid vacuum cooler is to put the high-temperature object into the vacuum chamber, and then the air in the vacuum chamber is extracted through the vacuum pump, so that it is in a vacuum state. The hot object is then cooled with a coolant to lower its temperature. The coolant can be liquid nitrogen, liquid oxygen, or other cryogenic liquids. Rapid vacuum cooling machine has the advantages of rapid cooling, precise temperature control and high reliability, so it is widely used in laboratory research, industrial production and medical fields. For example, in chemical, physical and biological experiments, rapid vacuum coolers can be used to quench samples quickly for more accurate experimental results. In industrial production, rapid vacuum coolers can be used to quickly cool high-temperature metal parts to prevent their deformation or damage. In the medical field, rapid vacuum coolers can be used to freeze viruses, cells and tissues for preservation and research.

Functional characteristics of Quick Freezing Equipment

The rapid vacuum cooler is an efficient cooling device with the following features:

1, rapid cooling: through the vacuum sealing system, the material is isolated from the atmosphere, reduce the ambient temperature, so that the material is quickly cooled in a short time.

2, vacuum sealing: The vacuum sealing system can prevent oxygen, moisture and other pollutants in the air from entering the material to ensure the quality and freshness of the material.

3, accurate temperature control: by controlling the vacuum degree and temperature, you can accurately control the cooling temperature of the material, improve the cooling efficiency and quality.

4, energy saving and environmental protection: The rapid vacuum cooling machine adopts the design concept of energy saving and environmental protection, the use of low-power vacuum pumps and sealing materials, reduce energy consumption and noise, and reduce the impact on the environment.

5, widely used: rapid vacuum cooling machine is widely used in food, medicine, chemical industry, metallurgy and other industries, can be used for cooling, drying, oxidation prevention, recycling and other purposes.

A rapid vacuum cooler is a device used to quickly cool hot objects. The working principle is to achieve rapid cooling by placing a high-temperature object in a vacuum chamber and taking advantage of the low temperature characteristics of the vacuum environment. Specifically, the higher the degree of vacuum in the vacuum chamber, the lower the temperature will be, causing the temperature of the object to drop faster. In addition, by changing the composition of the gas in the vacuum chamber, the cooling rate can also be changed.

Application field of Quick Freezing Equipment

The Rapid vacuum cooler is an efficient cooling device that can be used in a number of areas, including:

1, food industry: Rapid vacuum coolers can be used for food processing and storage to reduce the temperature of food and extend the shelf life of food.

2, pharmaceutical industry: Rapid vacuum coolers can be used for drug mixing and storage in the pharmaceutical process to ensure the quality and stability of drugs.

3, chemical industry: Rapid vacuum coolers can be used for material cooling in the chemical reaction process to control the reaction temperature and improve the reaction efficiency.

4, electronics industry: Rapid vacuum coolers can be used for cooling electronic components to prevent overheating and damage.

5, other application areas also include glass manufacturing, ceramic manufacturing, machinery manufacturing, etc.