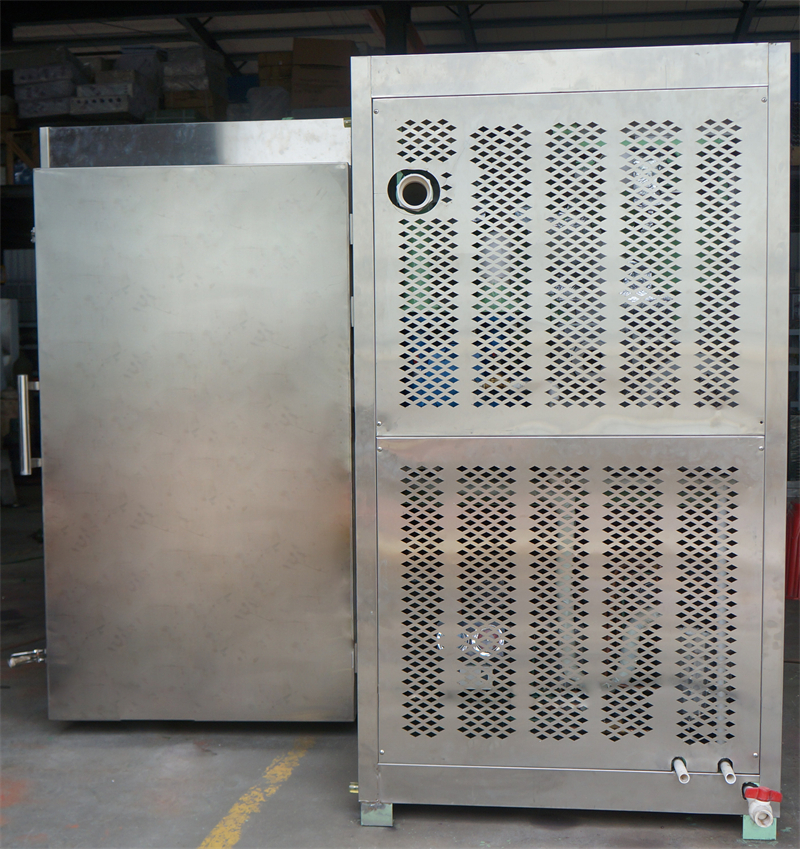

Bread vacuum cooler

Vacuum cooling machines for bread are specifically developed for the production of factory-made high-temperature cooked food. They are used to efficiently vacuum-cool rice, staple foods, pastries, fish, meat, poultry, fruits and vegetables, soy products, and other perishable items that require a longer shelf life without the use of preservatives. These devices rapidly cool down the food from high temperatures to room temperature or low temperatures. Vacuum rapid cooling machines are also suitable for processing fried foods with thicker fruit pulp layers.

Functional principle of bread vacuum cooling machine

1. Short cooling time and fast speed. The majority of high-temperature cooked foods can cool from 100℃ to room temperature in just 10-15 minutes, and reach below 0℃ in approximately 25-28 minutes, demonstrating extremely high production efficiency.

2. Uniform cooling temperature. Since the food's cooling temperature depends on the vacuum level inside the chamber, and the vacuum level (pressure value) is equal throughout the chamber, the food temperature remains highly uniform. During the vacuum cooling process, all parts of the food maintain a consistently decreasing temperature.

3. Sterilization during cooling process to avoid secondary contamination by the environment. Cooked foods cooled under sealed vacuum conditions are clean and hygienic without bacterial contamination; after completing vacuum cooling, pressurized air is introduced into the chamber which has been purified and filtered, free from suspended dust particles in ambient air, completely avoiding secondary contamination of food by airborne dust particles.

4. Cooling temperature can be flexibly adjusted according to actual production needs. In practical production, it is convenient to obtain desired temperatures for cooked foods by adjusting vacuum levels based on different products and requirements.

5. Improved quality of cooked foods. Due to short cooling times, reactions such as lipid oxidation and starch gelatinization that occur in food materials at high temperatures are avoided; simultaneously preventing biological fermentation (bacterial growth) occurring between 65℃ -30℃ for high-temperature food materials while enhancing reheating texture sensitivity fundamentally guarantees physiological conditions for long-term preservation of food; thus eliminating or reducing preservatives added to cooked foods making them truly "green" products.

6. Improve the taste of processed food products. Based on the principle of vacuum impregnation, it allows the concentrated broth (seasoning) that is lost due to dehydration on the outer surface of food to conveniently and quickly penetrate into the interior, thereby enhancing the flavor of the food.

7. The equipment has a small footprint. Since it does not generate any pollutants during operation, it can be directly installed in the production site of processed food, ensuring safety and hygiene.

8. Convenient and reliable operation. After setting up corresponding parameters, simply close the vacuum chamber door and press on the computer touch screen to automatically complete the entire cooling process.

9. Energy-efficient with low operating costs.

10. Affordable price, costing only about 1/3 to 1/2 compared to imported equipment.

11. According to different usage requirements, bread vacuum cooling machines can be divided into three major series: room temperature type, medium temperature type, and low-temperature type.

Bread vacuum cooler type

1. Constant temperature type: Since the working medium is water, the temperature of the working water directly affects the cooling final temperature. Generally, tap water is used as the working medium, and its temperature varies with seasons, resulting in a cooling final temperature that is generally 2-5℃ higher than the working water temperature; this is called constant temperature type.

- Suitable for products that are packaged immediately after cooling.

- However, if there is relatively stable groundwater or ice water available, a relatively stable and lower final temperature can still be achieved.

- Its characteristics include using an oil-free vacuum system which is not affected by steam impact; no condenser required and simple structure; high pumping speed and fast cooling; fewer moving parts and low failure rate; low cost. PLC touch screen display and operation.

- Cooling from 100℃ to room temperature only takes 12 minutes!

2. Medium temperature type: Although the cooling speed of medium-temperature type is slightly slower than constant-temperature type, it can cool to a lower temperature (15-20℃), and the final cooling point remains relatively stable without being influenced by external water temperatures like constant-temperature type does. Therefore, there are minimal seasonal differences in cooling quality with better assurance. In addition, intelligent pressure control technology effectively improves liquid splashing during vacuum cooling process.

- Cooling from 100℃ to below 20℃ only takes 15-20 minutes!

- Suitable for products with higher requirements on cooling process compared to constant-temperature type. PLC touch screen display and operation.

3. Low-temperature type:

- Can cool down processed items to below 10℃ in just 20-30 minutes.

-By applying our company's energy-saving and efficient water catcher, we have enhanced its ability to withstand thermal shocks, resulting in minimal temperature fluctuations and high water-catching efficiency. The PLC touch screen provides display and control capabilities.

- Applications of the vacuum rapid cooling equipment include vegetables such as leafy greens, stem vegetables, cauliflower, mushroom vegetables, etc.

-Staple foods such as rice, noodles, steamed buns (mantou), corn, dumplings (jiaozi), sushi, preserved fruits are also suitable for this equipment.

-Poultry dishes like steamed or boiled chicken and duck as well as saltwater goose can be prepared using this equipment.

- Meat dishes including steamed or boiled pork, beef, lamb, rabbit meat can also benefit from this technology.

- Fish and seafood items like river fish, sea fish varieties along with shellfishes like clams/shells (bei) shrimp (xia), crab (xie) can be processed using this equipment.

- Deep-fried food items such as fried snacks or fried meatballs are compatible with this machine.

- Baking products like mooncakes (yuebing), cakes (dangao), breads/loaves(baobing/mianbao), egg tarts/pies(danhuangpai) etc., can be produced using this device.

- Fillings for various food items including mooncake fillings(yuebing xian), tangyuan fillings(tangyuanshi xian)and other processed food ingredients can also be made using it

- Other applications include cooling and crystallization of high-temperature materials used in chemical industry processes and metal casting molds(such as sand).

Equipment parameters of bread vacuum cooler(The following parameters are for reference only, depending on the device model)

1. Equipped with imported dual vacuum pumps with gas suppression, which can automatically adjust the vacuum energy and also have a backup option.

2. Designed with a patented large heat capacity, shock-resistant, and energy-saving all-stainless steel water trap. This overcomes the problems of multiple welding points in copper coils, difficult welding to the shell, and easy leakage. It solves the impact of a large amount of water vapor "flashing" on refrigeration and vacuum systems, has minimal fluctuations in water trapping temperature, excellent water trapping effect, low equipment failure rate, and long service life.

3. Equipped with thin-film capacitor vacuum sensors and probe-type metal shielded temperature sensors for high precision measurement components.

4. Configured with imported vacuum valves that have sensitive and reliable actuation mechanisms.

5. Unique voltage stabilization control system that allows adjustable cooling rates while having anti-cold damage functions.

6. Precision CNC machining technology ensures equipment's vacuum leak rate is less than 1×10-2mbar/L/sec.

7. Has an automatic/manual dual operating system

8. Configured with advanced PLC touch screen control system that displays clearly; it is easy to operate professional hierarchical management design along with password protection making it safe & reliable

9. Offers various (manual/foot-operated/electric) lifting ramps available for selection to save time & effort during loading/unloading goods

10.Can produce multiple vacuum boxes connected as one system; this makes it more energy-efficient & efficient overall

11.Working voltage: AC380V (three-phase five-wire), A/B/C three-phase plus N (zero), E (ground) line