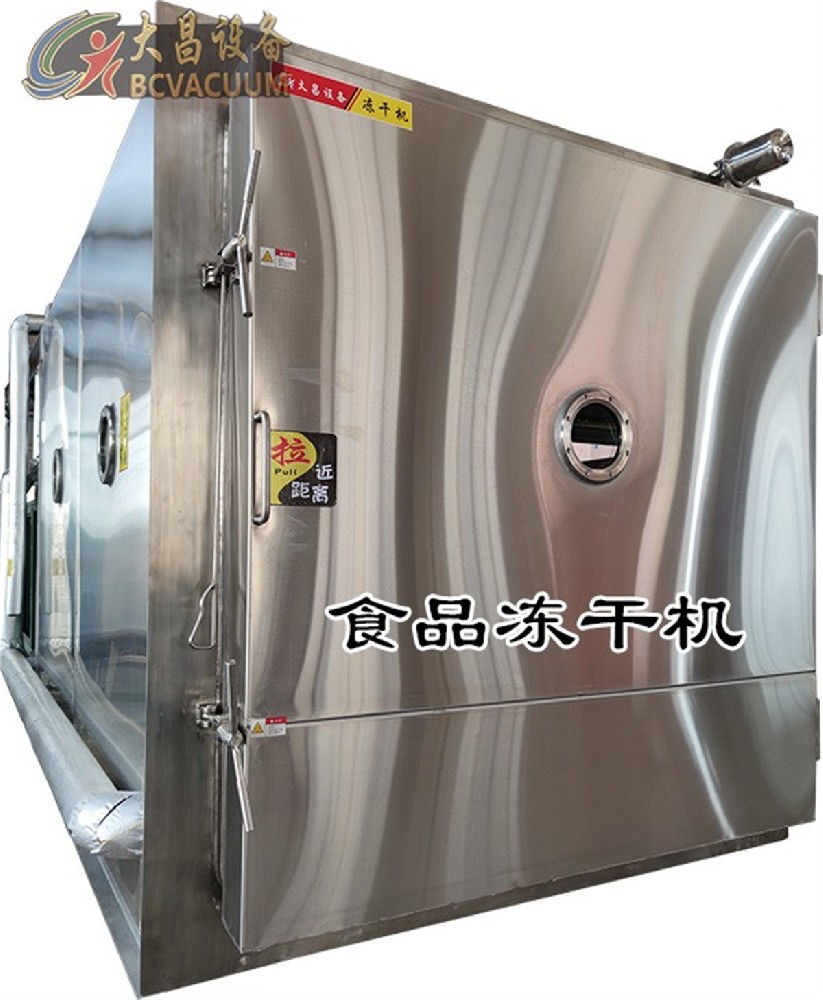

Ready Food Vacuum Cooling System

The principle of the cooked food vacuum precooling machine is to use a vacuum pump to extract the air from the vacuum chamber so that it is in a vacuum state. At the same time, the heater precools the materials in the vacuum chamber. In this vacuum environment, the moisture in the material will evaporate quickly, causing the temperature of the material to drop, achieving the purpose of pre-cooling. In addition, the vacuum precooling machine can also change the air pressure and temperature in the vacuum chamber to change the cell tissue in the material, thereby improving the texture, taste and nutritional value of the material. In short, the cooked food vacuum pre-cooling machine achieves the purpose of rapid pre-cooling and improving the texture of materials through the action of vacuum environment and heater, and is widely used in food, medicine and other industries.

Fresh food cooler Function:

Pre-cooling: quickly cool hot cooked food to the appropriate storage temperature to extend the shelf life.

Drying: In a vacuum state, the material is dried through a heater to reduce the moisture content in the material and improve the quality and taste of the material.

Sterilization: In the vacuum state, it can effectively kill bacteria in the material and improve the hygienic quality of the material.

Improve texture: By changing the air pressure and temperature in the vacuum chamber, the texture, taste and nutritional value of the material can be improved.

Energy saving and environmental protection: Compared with traditional cooling methods, vacuum precoolers have the advantages of energy saving and environmental protection, which can reduce energy consumption and exhaust emissions.

Application areas of Cooked food real air speed cooling machine :

Cooked food vacuum pre-cooling machine is mainly used in food, medicine and other industries. Specific application areas include:

Cooked food processing: The cooked food vacuum pre-cooling machine can be used to quickly reduce the temperature of cooked food, thereby extending the shelf life and improving quality and taste.

Aquatic product processing: Vacuum precooling machine can be used to precool fish fillets, shrimp and other materials in aquatic product processing, effectively maintaining their nutritional value and taste.

Vegetable processing: Vacuum precooling machine can be used to quickly cool down vegetables in processing, thereby maintaining their freshness and taste.

Pharmaceutical production: Vacuum precooling machine can be used to precool and dry drugs, biological products and other materials in pharmaceutical production, thereby maintaining their quality and activity.

Chemical production: Vacuum precooling machine can be used to precool and dry raw materials and products in chemical production, thereby improving production efficiency and quality.

In short, cooked food vacuum precooling machines are widely used in food, pharmaceutical and other industries, and can effectively improve the quality and shelf life of materials.

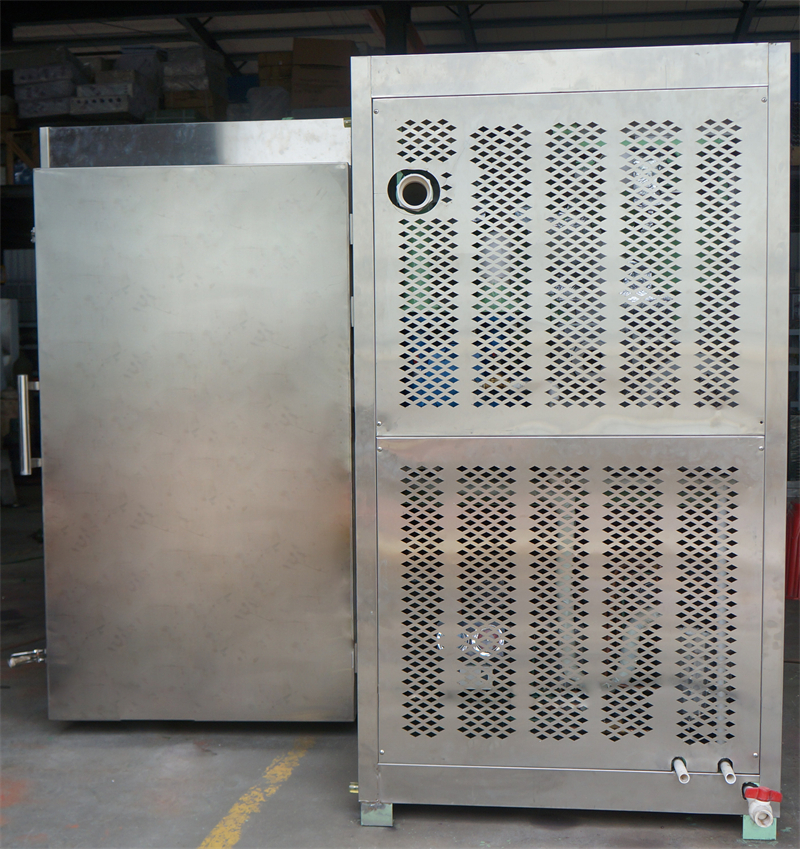

Specification of Vacuum precooler for cooked food

Vacuum degree: Vacuum degree refers to the air pressure value in the vacuum chamber, usually expressed in Pa or kPa. The higher the vacuum degree, the lower the air pressure in the vacuum chamber, the faster the evaporation rate of water in the material,and the better the pre-cooling effect.

Precooling temperature: Precooling temperature refers to the temperature in the vacuum chamber, usually expressed in ℃ or °F. The lower the precooling temperature, the better the precooling effect of the material.

Pre-cooling time: Pre-cooling time refers to the time the material stays in the vacuum chamber, usually expressed in minutes or hours.The longer the pre-cooling time, the better the pre-cooling effect of the material.

Cooling capacity: Cooling capacity refers to the amount of material that the vacuum cooler can handle per hour, usually expressed in kg or lb. The greater the cooling capacity, the stronger the processing capacity of the vacuum cooler.

Model size: Model size refers to the size and weight of the vacuum cooler, usually expressed in mm or in. The size of the machine should be selected based on the actual application scenario and material volume.

It should be noted that different materials and different application scenarios require different parameters of the cooked food vacuum precooler. Therefore, when selecting and using the cooked food vacuum precooler, you need to select and configure it according to the specific situation.