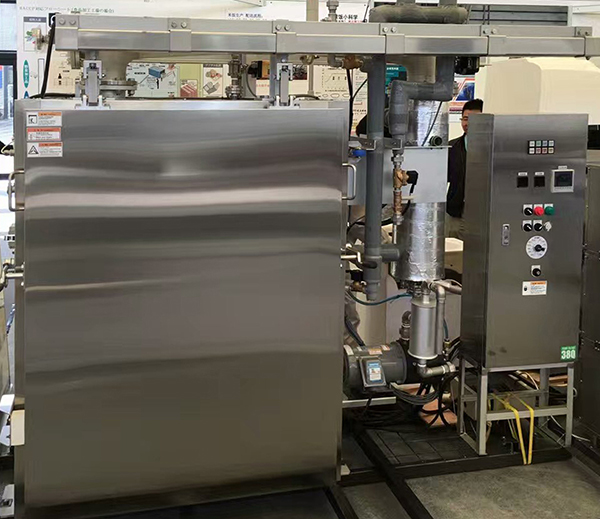

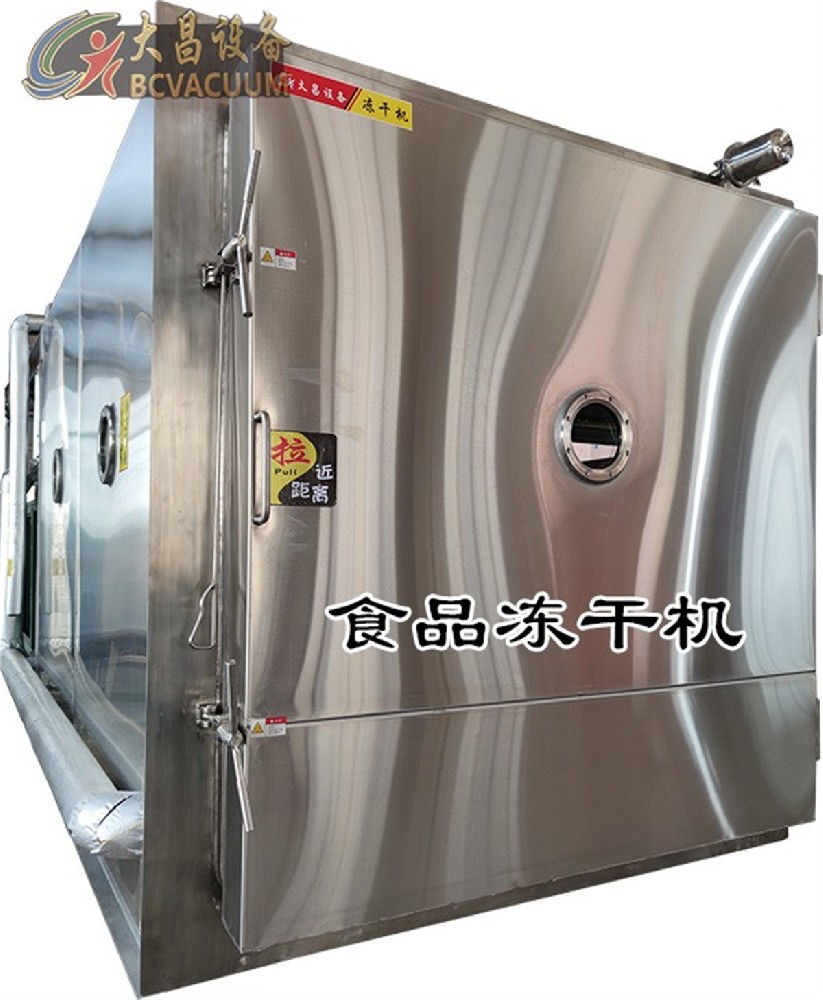

Functional principle of fast vacuum rapid cooling machine

The rapid vacuum cooling machine is developed for the production of high-temperature steamed food in factories. It is an efficient vacuum cooling treatment equipment used for rice, staple foods, pastries, fish, meat, poultry, fruits and vegetables, bean products, and other products that require no preservatives to ensure shelf life, and for food to quickly cool from high temperature to room or low temperature. The vacuum rapid cooling machine is also suitable for the cooling and processing of fried foods with thick flesh layers.

1. Short cooling time and fast speed. The vast majority of high-temperature cooked foods only take 10-15 minutes to cool from 1 OO ℃ to room temperature, and about 25-28 minutes to cool below 0 ℃, demonstrating extremely high production efficiency.

2. The cooling temperature is uniform. Due to the fact that the cooling temperature of food depends on the vacuum degree inside the tank, and the vacuum degree (pressure value) inside the tank is equal everywhere, the food temperature is very uniform; The temperature of each part of the food in the vacuum tank remains uniformly decreasing during the vacuum cooling process.

3. The cooling process is sterile, avoiding secondary environmental pollution of food. Cooked food cooled in a sealed vacuum state is clean and hygienic, without bacterial contamination; After vacuum cooling is completed, the tank body is re pressurized and air is introduced. The air is purified and filtered, and does not contain dust suspended substances in the air, completely avoiding secondary pollution of food caused by dust suspended substances in the air.

4. The cooling temperature can be flexibly adjusted according to actual production needs. In actual production, the temperature required for cooling cooked food can be conveniently obtained by adjusting the vacuum degree according to different products and needs.

5. Improve the quality of cooked food. Due to the short cooling time, it can avoid reactions such as oil oxidation and starch gelatinization that occur in food materials at high temperatures; At the same time, it also avoids the biological fermentation (bacterial reproduction) generated by high-temperature food materials at 65 ℃ to 3 O ℃, and improves the taste of the returned pot, fundamentally ensuring the physiological conditions for long-term preservation of food; In this way, a large amount of cooked food avoids adding preservatives, making it a true "green food".

6. Improve the taste of cooked food products. Based on the principle of vacuum impregnation, the concentrated soup (seasoning) from the outside of the food due to water loss can be easily and quickly introduced into the inside of the food, thereby improving the taste of the food.

7. The equipment occupies a small area. Due to its operation without generating any pollutants, it can be directly installed on the production site of cooked food, ensuring safety and hygiene.

8. Convenient operation and reliable operation. After setting the corresponding data, close the vacuum box door and press the computer touch screen to automatically complete the entire cooling process.

9. Low energy consumption and low operating costs.

10. The price is cheap, and its cost is only about one-third to half of that of imported equipment.

11. According to different usage requirements, cooked food vacuum coolers can be divided into three series: room temperature, medium temperature, and low temperature.

Types of rapid vacuum cooling machines

1、 Normal temperature type

Because the working medium is water, the temperature of the working water directly affects the final cooling temperature. Generally, tap water is used as the working medium, and the temperature of tap water varies with the season, and the final cooling temperature also changes accordingly, generally 2-5 ℃ higher than the working water temperature; It is called a room temperature type.

1. Suitable for products that are packaged and shipped immediately after cooling.

2. But if there is groundwater or ice water with relatively constant water temperature, a relatively stable and low final temperature can still be obtained.

3. Its characteristic is the use of an oil-free vacuum system, which is not afraid of water vapor impact; No water trap, simple structure; Large pumping speed and fast cooling; Few moving parts and low failure rate; Low cost. PLC touch screen display and control.

4. Cooling from 100 ℃ to room temperature only takes 12 minutes!

2、 Moderate temperature type

Although the cooling speed of the medium temperature type is slightly slower than that of the room temperature type, it can be cooled to a lower temperature (15-20 ℃), and the cooling endpoint temperature is relatively constant, unlike the room temperature type, which is affected by external water temperature. Therefore, the seasonal differences are not significant, and the cooling quality is more guaranteed. In addition, intelligent pressure control technology has effectively improved the problem of liquid splashing during vacuum cooling;

Cooling from 100 ℃ to below 20 ℃ only takes 15-20 minutes!

Suitable for products with high cooling process requirements.

At room temperature; PLC touch screen display and control.

3、 Low temperature type

1. The processed material can be cooled to below 10 ℃ in just 20-30 minutes.

2. The energy-saving and efficient water catcher developed by our company has improved the ability of the water catcher to resist thermal shock, with small temperature fluctuation and high water capture efficiency; PLC touch screen display and control.

3. Vacuum rapid cooling equipment usage: Vegetables: leafy vegetables, stem vegetables, cauliflower, mushroom vegetables, etc

4. Staple food: rice, noodles, Mantou, corn, dumplings, sushi, preserved fruit, etc

5. Poultry category: steamed chicken and duck, salted goose, etc

6. Meat category: steamed pork, beef, sheep, rabbit meat, etc

7. Fish and shrimp: river fish, sea fish, shellfish, shrimp, crabs, etc

8. Fried food: fried food, fried balls

9. Baking category: mooncakes, cakes, bread, egg yolk pies, etc

10. Filling materials: moon cake filling, dumpling filling, conditioning food, etc

11. Other categories: chemical high-temperature material cooling and crystallization, metal casting sand, etc

Parameters of fast vacuum rapid cooling machine

1. Equipped with imported double vacuum pumps with gas ballast, which can automatically adjust Vacuum energy, or one for use and one for standby;

2. Equipped with patented design of high heat capacity impact resistant energy-saving all stainless steel water catcher. Overcoming the problems of multiple solder joints in copper coil pipes, difficulty in welding with the casing, and easy leakage; Solved the impact of a large amount of water vapor "flashing" on refrigeration and vacuum systems, resulting in small fluctuations in water capture temperature, good water capture effect, low equipment failure rate, and long service life;

3. Equipped with thin film capacitive vacuum sensors and probe type metal shielding temperature sensors, the measurement element has high accuracy and precision;

4. Equipped with imported vacuum valves, the actuator operates sensitively and reliably;

5. A unique voltage stabilizing control system with adjustable cooling rate and anti cold damage function;

6. Precision CNC machining technology ensures that the vacuum leakage rate of the equipment is less than 1 × 10-2mbar/L/sec;

7. Equipped with automatic and manual dual operation system;

8. Equipped with advanced PLC and touch screen control system, with clear display and convenient operation, professional hierarchical management and password protection design, safe and reliable;

9. There are various (manual, pedal or electric) lifting slopes to choose from, making cargo loading and unloading more time-saving and labor-saving;

10. Multiple vacuum box parallel systems can be produced, with one machine for multiple purposes, which is more energy-efficient and efficient.

11. Working voltage: AC380V (three-phase five wire), including A, B, C three-phase plus N (zero) and E (ground) lines.