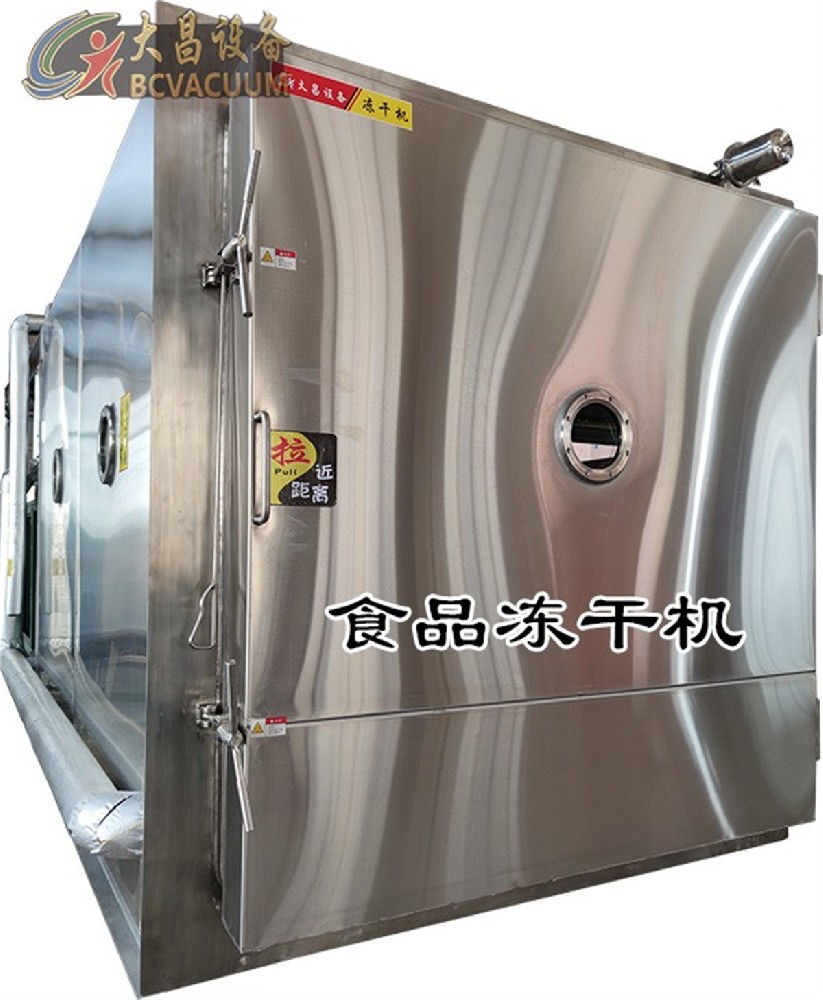

Vacuum odor removal equipment

Vacuum odor removal equipment is widely used in tobacco industry and food packaging printed matter. The tobacco industry is organizing the implementation of an industry standard (limit indicator of volatile organic compounds (V0Cs) in cigarette bars and packaging). For a long time, the volatile odor substances produced in the printing of cigarette packaging paper have not been effectively controlled, and there is a large gap with well-known foreign brands. If used to package food, it will directly contaminate food. Affecting the health of consumers. According to this, Dachang Air conditioning equipment company and tobacco printing professional and technical personnel cooperation, according to the requirements of the printing process, Dachang company designed the use of vacuum (negative pressure) method to remove odor, which is a new technology to solve the solvent residue in the cigarette strip and box wrapping paper and various odor limits. It has been proved by users that it can significantly improve production efficiency and product quality. This set of equipment has large daily processing capacity, convenient operation and reliable operation, and is an ideal supporting equipment for cigarette label printing enterprises.

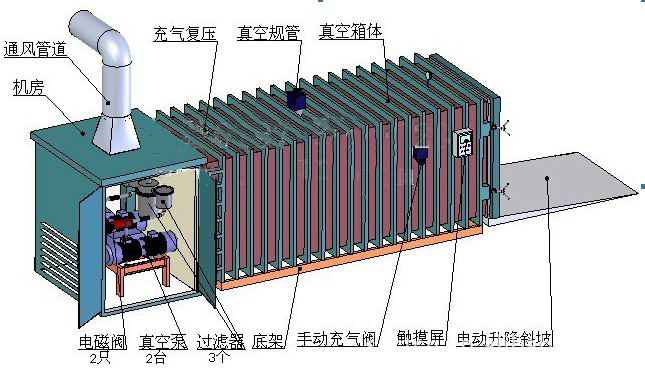

Principle of Vacuum odor removal equipment

1, the product (printed matter) is placed in the vacuum tank, pumped by the vacuum pump, with the reduction of the pressure in the tank, the volatile

odor substances in the printing material on the paper accelerate volatilization, under the action of the pressure difference, and the molecules that

have been volatilized on the surface, leave the surface to the space diffusion, and are discharged to the outdoor vacuum pump. Because the overlap

between the paper is relatively tight, the diffusion of odor molecules in the middle part is not smooth, and a certain time process is required, and the

pumping time is proportional to the paper area and the stacking thickness. The water loss of degassing paper is inversely proportional to the pressure

and proportional to the time, and the user has proved that the equipment meets the design requirements, the effect is ideal, and the odor removal work

can be completed in 2-3 hours.

2, the vacuum deodorizer makes the product in the vacuum dynamic pressure state, the odorous substances in the product are rapidly removed from

the adsorption surface under the action of fluctuating pressure difference, and are discharged to the outside by the vacuum pump, so as to achieve

the effect of deodorization. Compared with the traditional method, the vacuum deodorizer can significantly shorten the dispersing time and

greatly improve the production efficiency and product quality.

Equipment characteristics of Vacuum odor removal equipment

1, intelligent program controlled vacuum dynamic pressure technology to ensure the efficiency and uniformity of product flavor removal;

2, with automatic and manual dual operating system;

3, with pressure and time two sets of control system;

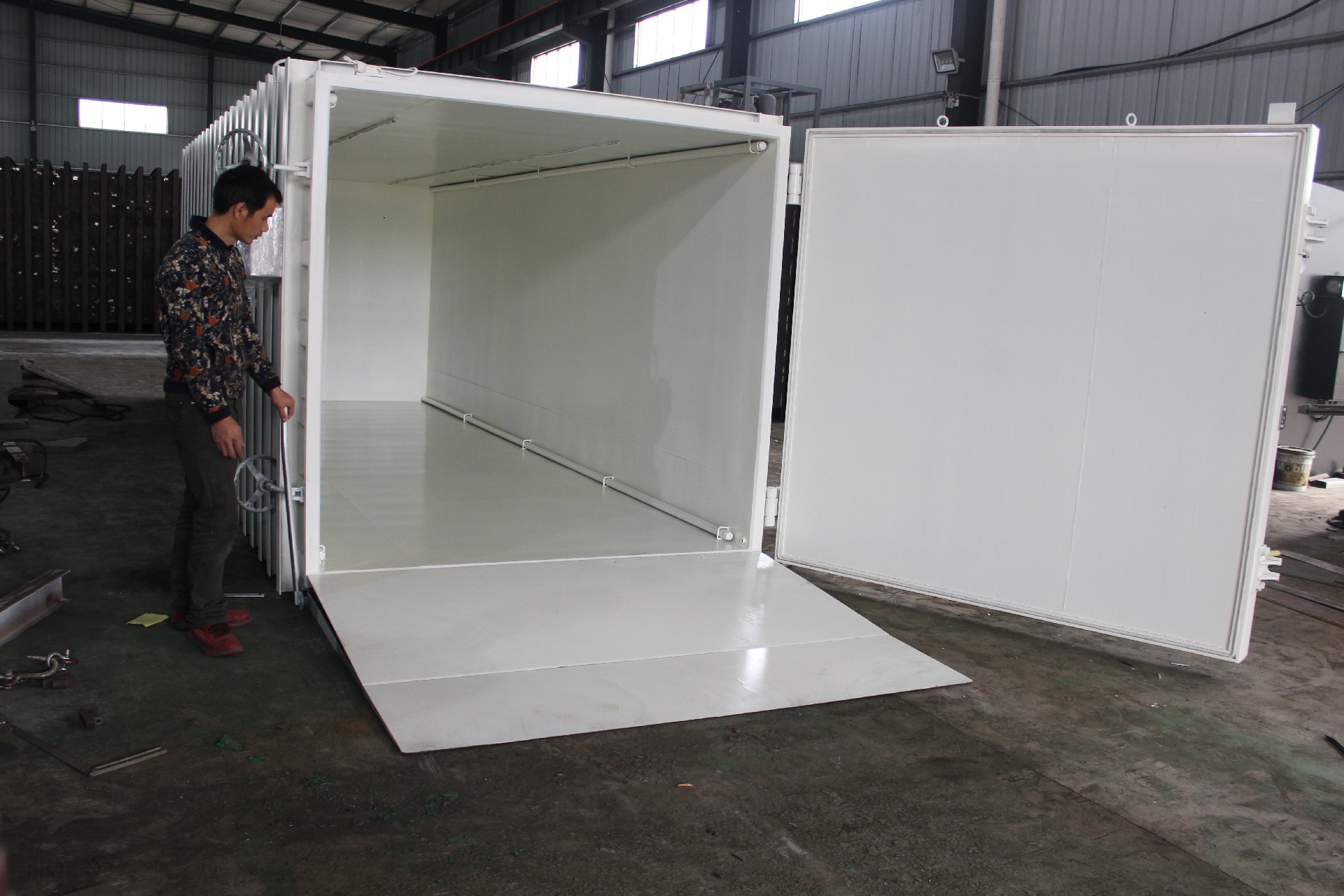

4, equipped with electric lifting slope, save time and labor for users to load and unload goods;

5, equipped with efficient vacuum pumping device, to the limit vacuum time is less than 15 minutes;

6, the unique fast inflation device system, higher odor removal efficiency;

7, the user can set the processing method and time according to the process needs;

8, equipped with advanced PLC, touch screen control system;

9, optional infrared heating device, wider applicability, better effect, higher production efficiency;

10, optional multi-empty box parallel system, a multi-purpose machine, more energy saving, more efficient;

11, optional real box infrared video security monitoring system.

Technical parameter of Vacuum odor removal equipment

Model Empty box capacity Processing time Limit vacuum degree (empty box) Pumped to limit vacuum degree time Total installed power weight

(m3) (T) (h) (Pa) (min) (KW) (T)

DC-15 15. 3-5 1-2 ≤400 ≤15 14(380V) 7.50

Scope of application

Vacuum deodorizer is suitable for quickly removing benzene, toluene, formaldehyde, ethylbenzene, butanone and other volatile organic compounds

contained in cigarette label paper, food wrapping paper, tableware, wood-based board, furniture, etc. It has played an important supporting role in the

implementation of the standard of "The Limit index of Volatile Organic Compounds (VOCs) in the paper packaging materials of cigarette bars and

boxes" in the cigarette label printing industry.